design and description of sgv7 gas-liquid separator

The separator's operating principle is based on the synergistic use of centrifugal and gravitational forces, which are the primary separation forces for the gas-liquid flow entering the SGV-7 separator. The separator also partially utilizes the vortex effect that occurs when the flow enters a centrifugal force field.

The internal components of the separator are designed to separate suspended moisture and mechanical impurities from the gas flow.

The internal elements of the separator do not contain rotating parts, filters or other dynamic or replaceable elements that require periodic inspection, maintenance, repair or replacement. This makes the design of the SGV-7 separator more reliable, adapted to difficult operating conditions in both compressed air preparation systems and gas field conditions.

The internal elements of the SGV-7 separator are optimally designed to prevent wear during operation in an abrasive environment. Mechanical impurities contained in the gas stream do not harm or wear out the separation elements of the separator structure due to their optimal location, uniform distribution and direction of the abrasive flow into the separation zone of mechanical impurities, where they practically do not interact with the internal elements of the separator.

The principle of operation of the separator is based on the synergistic use of centrifugal and gravitational forces, which are the main separating forces for the gas-liquid flow entering the SGV-7 separator. The vortex effect that occurs when the flow enters the field of centrifugal forces is also partially used in the separator operation.

At the same time, the purification of the gas stream from suspended moisture and mechanical impurities occurs in several stages, which have increased separation efficiency characteristics, which make it possible to confidently separate droplet moisture and mechanical impurities from the gas stream even in modes beyond the designed ones. Thus, the SGV-7 separator has a stable separation efficiency of 99.99% and an entrainment of 4-6 mg/ norm. cubic meters with a capacity from 30 to 130% of the nominal value. The operating pressure of the separation process has virtually no effect on the efficiency of the separator and can vary over a wide range when the SGV-7 separator is operating.

The separation elements located inside the separator are designed to be optimally configured in the laboratory. During laboratory tests, the main focus was on increasing the efficiency of separation and minimizing pressure losses on the apparatus. Thus, the SGV-7 separator has a high separation efficiency and minimal pressure loss on the device, amounting to 0.01-0.02 atm. The pressure loss at the separator largely depends on the amount of liquid contained at the inlet to the separator, and in the case of plug operation of the separator is no more than 0.4 atm.

As is known, the plug mode of operation of the separator occurs when liquid enters the inlet pipe of the separator in a single burst. Such a situation is highly probable when the separator is operating at the UCP. The plug mode is characterized by high flow rates when entering the separator, significant hydrodynamic loads on the internal elements of the separator, and significant pressure drops on the apparatus. The tests of the SGV-7 separator showed stable operation of the separator in the plug mode, the absence of flow blocking in the separator, significant separation efficiency and a slight pressure drop.

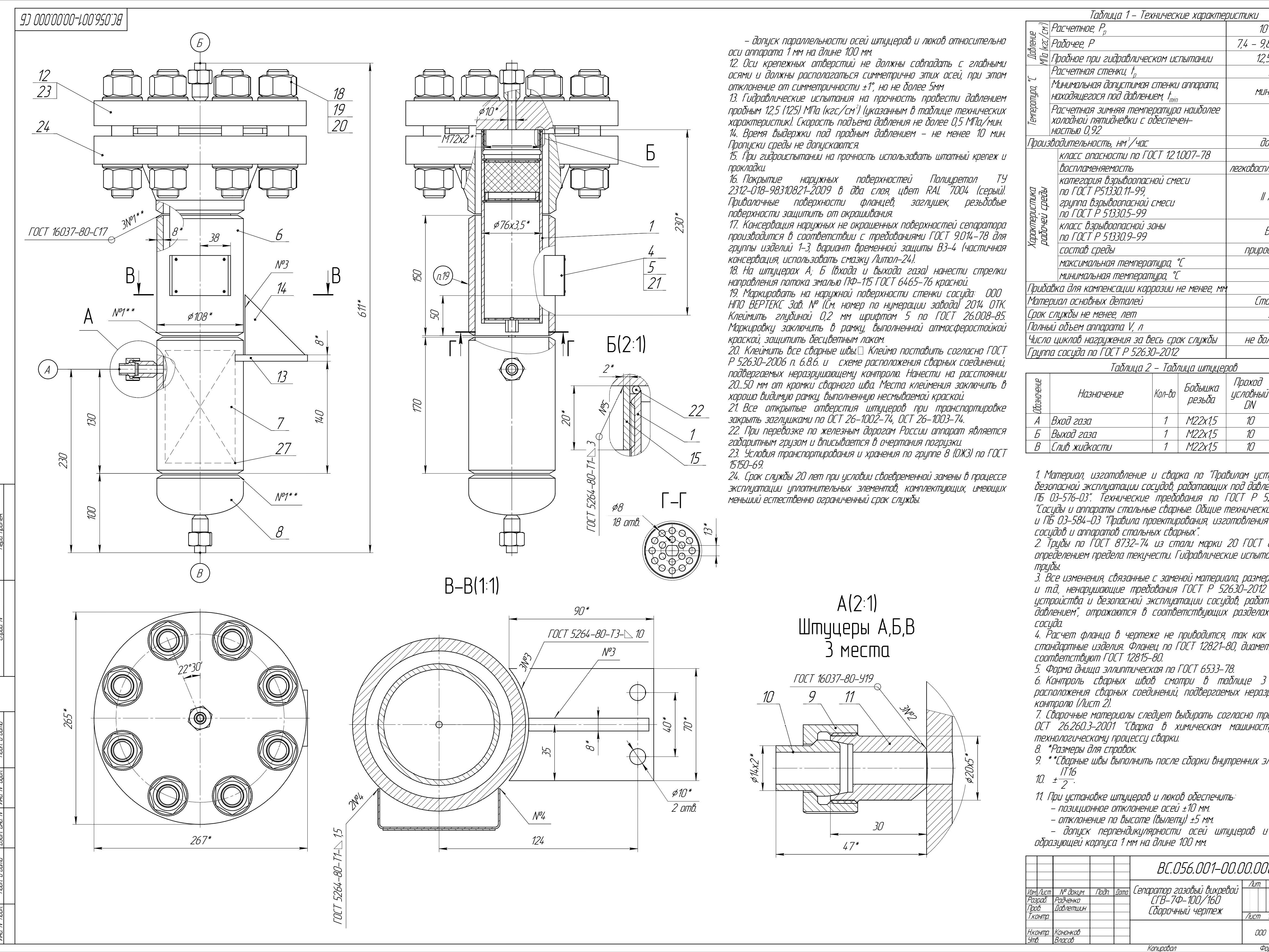

The proposed design of the SGV-7 separator can have a storage tank for liquid both combined with the separator body (most effectively with large diameters of the separator body) and a separate tank. At the same time, the storage tank of the separator can be equipped with level sensors, visual level monitoring devices, temperature and pressure sensors, pressure gauges, thermometers. The storage tank (combined or separate) can also be equipped with a liquid discharge unit and automatic discharge.

The manufactured block separation units are manufactured in high factory readiness, which significantly reduces the time required for installation and commissioning of equipment at the facility. Automation of installations can be integrated into the automated control system of the facility

The patented design of the SGV-7 separator has an increased throughput due to the optimal design of the internal elements. This, in turn, leads to a decrease in the overall mass characteristics of the separator compared to its analogues. In addition, the horizontal arrangement of the gas outlet pipe also reduces the construction height of the device and optimizes construction work on the site. As a result, this leads to a reduction in the metal consumption of the separator and a reduction in its cost.

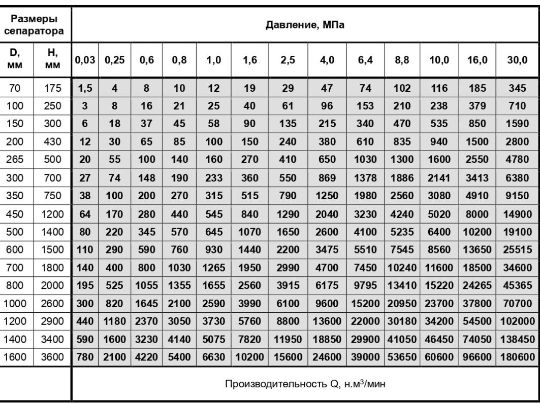

The approximate dependence of the overall dimensions of the SGV-7 separator on the operating pressure and productivity is shown in the table.

VERIFIED • FAST • RELIABLE

* Questionnaires without feedback contacts are not processed

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.