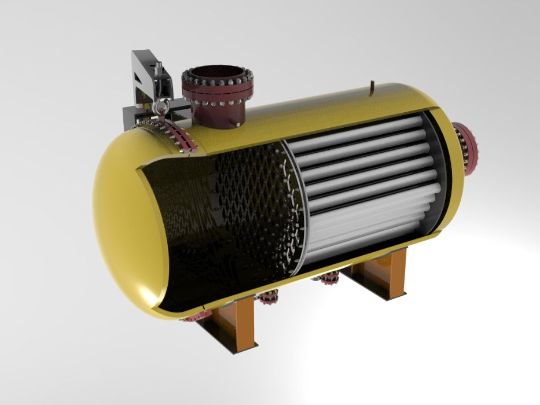

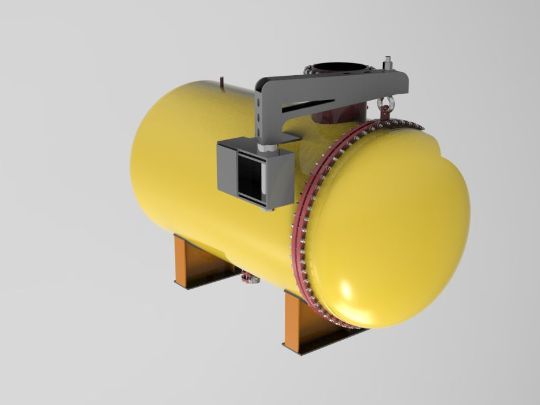

Horizontal filter separator for mechanical impurities

To purify the gas stream from mechanical impurities, a filter separator with filter cartridges designed to capture solid particles is used.

There are several limiting parameters that allow you to choose the right filter separator for correct operation.

The main technical characteristics and operation description of the filter separator are given below.

The filter separator with coagulating type cartridges is designed to purify dry gas without liquid droplets from mechanical impurities and rust in the gas stream.

The device is a cylindrical pressure vessel with a body flange mounted on studs.

A lifting and turning device is used to open the housing flange, which allows full access to the internal devices of the filter separator and to replace expired filter cartridges.

The diameter of the filter separator housing corresponds to the gas capacity of the device and contains in its design the necessary number of filter cartridges necessary to ensure gas performance under current operating technological conditions and the necessary dust capacity.

The pressure drop across the filter cartridge is 0.1 atm. The maximum possible pressure drop allowed before the cartridge collapses is 2 atm.

Filter cartridges are available with any size of cell porosity and can be manufactured for sizes of mechanical impurities from 1 microns to 200 microns.

To capture mechanical impurities of more than 200 microns, it is possible to use stainless steel cartridges with the required cell porosity.

capacity of the filter separator in n.m3/hour

The table shows the performance of the gas separator filter depending on the diameter of the housing and the operating pressure. The green column indicates the number of filter cartridges with a length of 1800 mm, which is the minimum required to ensure such performance at the specified pressure.

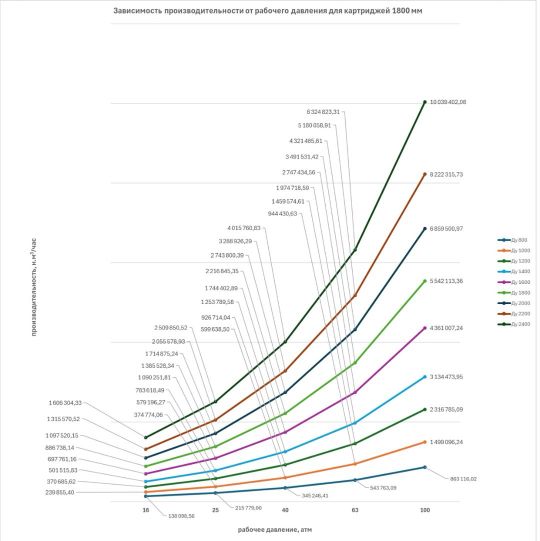

graph of the performance of the filter separator for each case diameter

The graph shows the performance versus operating pressure for each diameter of the filter separator housing. A filter separator with coagulating cartridges for mechanical impurities with a length of 1800 mm was adopted as the most optimal and most commonly used filter cartridge.

The use of standard cartridges allows for on-site unification to optimize the cost of periodic maintenance of filter separators.

To ensure long-term operation of the filter elements, cyclone dust collectors can be installed in front of the separator filter to reduce the amount of mechanical impurities that enter the filter cartridges of the horizontal separator filter.

The use of cyclone dust collectors based on SGV-7 separation elements significantly increases the uninterrupted service life of filter separators and increases the duration of the interval between cartridge replacements due to better separation of mechanical impurities from the gas stream in front of the filter separator.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.