Operation gas desiccant filters

The main gas pipelines are operated in difficult climatic conditions.

The actuating mechanisms of the cranes of the main gas pipeline use pulsed gas, which is powered from gas transported through the main gas pipeline. To ensure uninterrupted power supply to the actuators, the pulse gas must be prepared to the required conditions to prevent impurities from entering the pneumatic cylinders of the crane actuators. In addition, to prevent over-freezing of the actuators, the pulse gas must be drained to a dew point temperature below the ambient temperature.

The relevance of using a operation gas desiccant filter

The operating conditions of the main gas pipelines imply laying the route along the shortest route from the source to the consumer. This causes the passage of the main gas pipeline route often in hard-to-reach places with a harsh climate.

Sometimes the ambient temperature in the places where the main gas pipeline passes can reach -60 degrees Celsius.

Such operating conditions of equipment designed for trouble-free operation of the pipeline cause increased requirements for actuators installed on the drive fittings of valve spots and other actuators on the drive fittings.

Operation gas desiccant filters are used to ensure the smooth operation of actuators operating on operation gas.

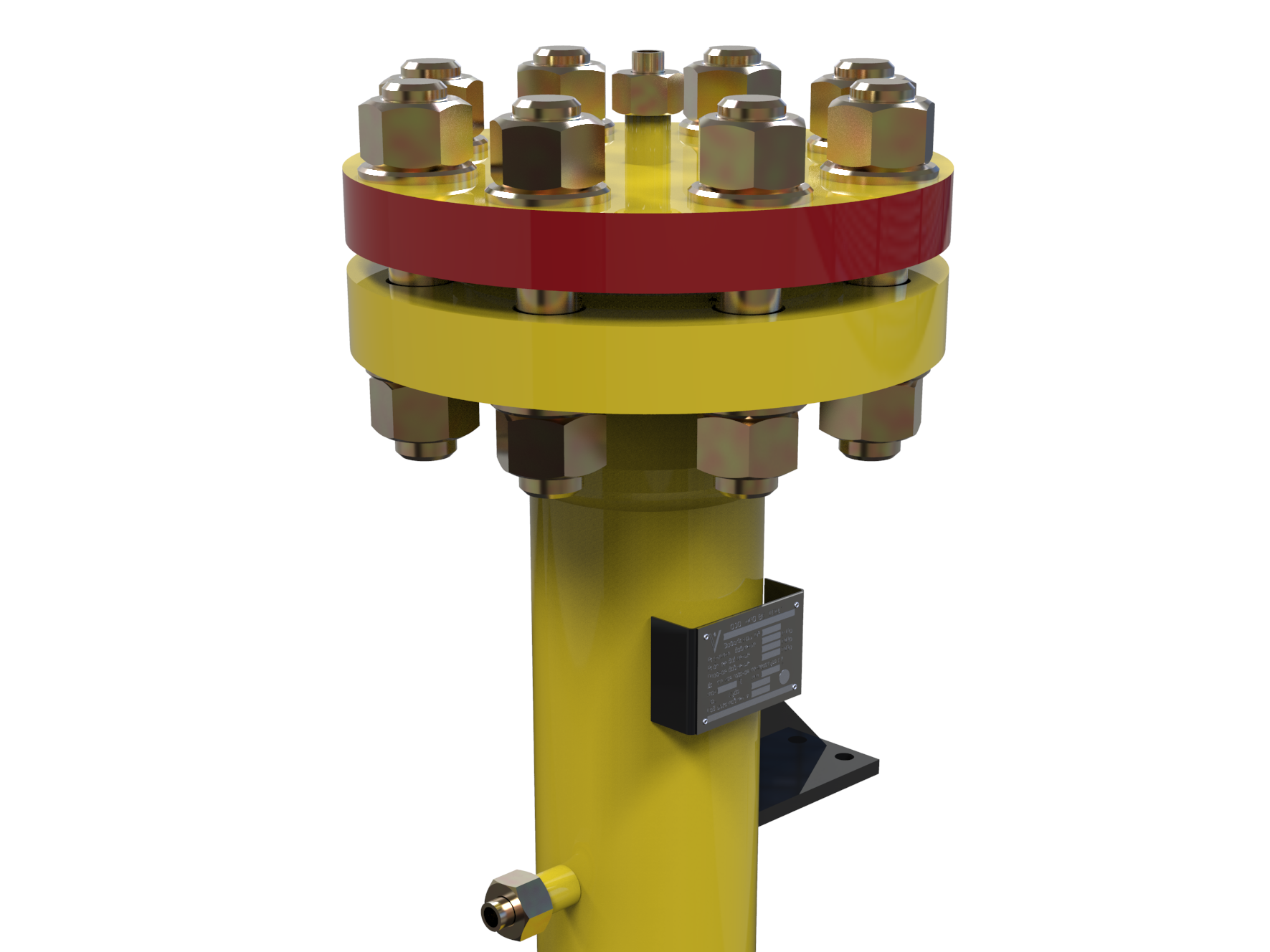

To ensure the smooth operation of the actuators, we have developed a design of special filters for operation gas dryers, which provides for a three-stage purification of gas from droplet liquid and mechanical impurities and ensures gas drying by lowering the dew point temperature to values below the ambient temperature.

This arrangement of the internal devices of the dehumidifier filter allows not only to ensure the necessary quality of gas treatment, but also to guarantee the reliability of the dehumidifier filter in conditions of difficult transport accessibility of the valve spots of the main gas pipeline.

The dehumidifier filter has increased requirements in terms of manufacturing quality and uptime. In addition, the volume of gas passed through is also regulated to ensure the required number of guaranteed actuations of the valve actuator.

The design of the dehumidifier filter is simple and reliable, which ensures uninterrupted operation of the actuators throughout the entire service life of the dehumidifier filter.

description of the design of the pulsed gas desiccant filter

The developed design contains three stages of purification and drying of operation gas. The SGV-7 dehumidifier separator is installed on the first stage, which purifies the operation gas from the available droplet moisture and removes it to the lower part of the dryer filter housing.

In this case, the dehumidifier separator is located in a single housing with the rest of the structural elements.

The separated moisture is removed from the lower part of the SGV-7 dehumidifier through an automatic condensate trap in automatic mode as it accumulates or remains in the storage part of the separator housing (depending on the design of the filter dryer housing) from where it is subsequently discharged during periodic inspection and maintenance by personnel.

justification of the adsorbent application

At the second stage of air purification, an adsorbent cartridge is installed, which is designed to remove dissolved moisture from the operation gas.

The moisture contained in the operation gas accumulates in the adsorbent, being removed from the gas stream during operation of the desiccant filter, which significantly lowers the temperature of the dew point of the operation gas.

At the same time, the resource of the adsorbent (selikagel + zeolite) is significantly increased, since the main droplet moisture was removed at the SGV-7 separation element, which is installed at the first stage of purification.

This arrangement of the separation element and adsorbent significantly increases the service life of the adsorbent used, since it prevents moisture from entering the adsorption stage, as a result of which the adsorbent is saturated with moisture in a more gentle mode.

A filter cartridge is installed at the third stage of operation gas purification. The filter cartridge is designed for additional, final capture of both droplet moisture and traces of adsorbent decomposition from the operation gas stream.

The use of a filter cartridge makes it possible to completely eliminate the ingress of both moisture and mechanical impurities onto the actuators and pneumatic cylinders used on crane platforms.

The three-stage alignment is the most reliable way to ensure the quality of operation gas treatment and protect the actuators from all types of contamination that may be present in the transported gas in the main gas pipeline.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.