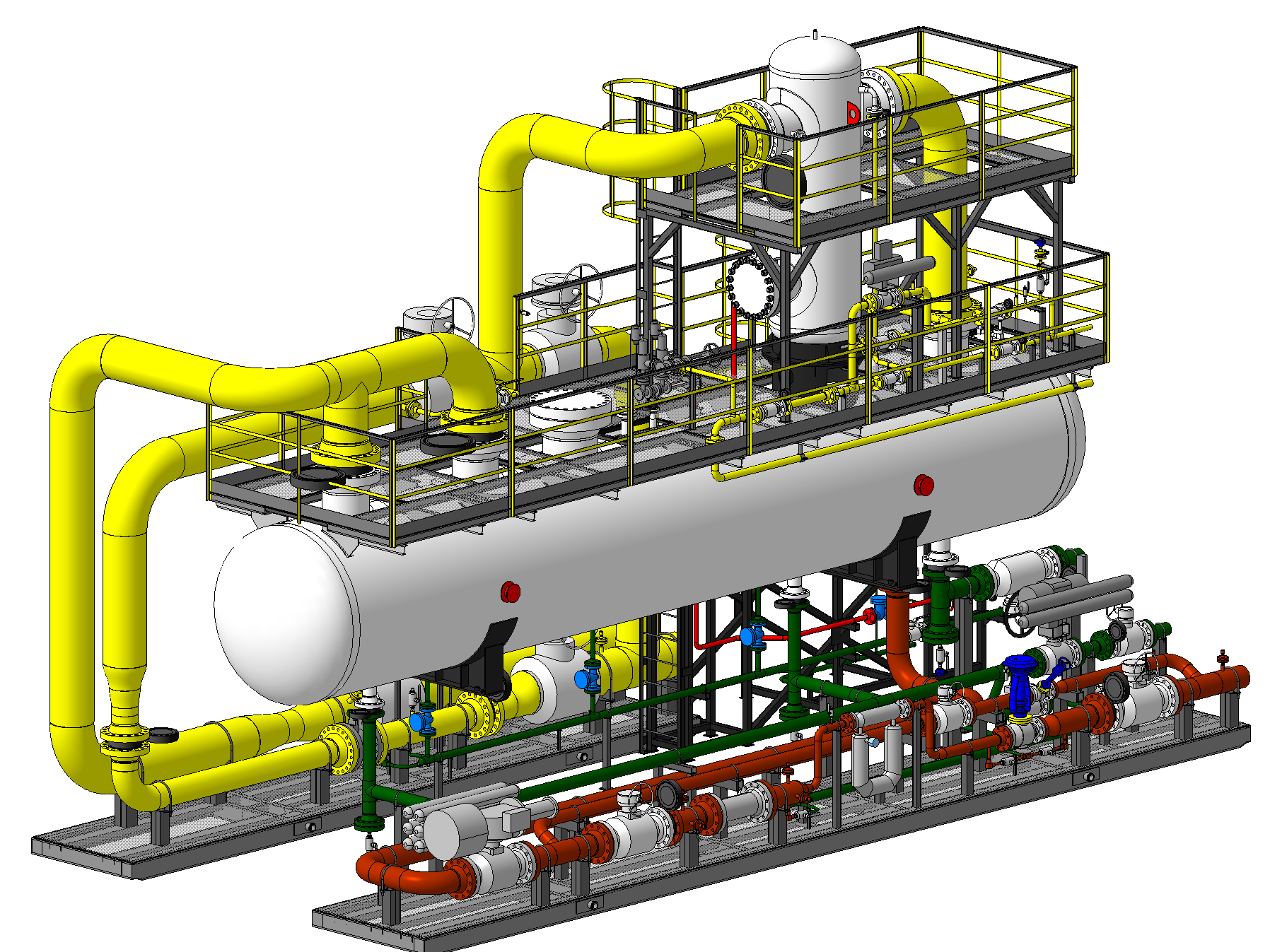

block separation unit

The block separation unit based on the SGV-7 gas separator has a high factory availability, as a result of which it significantly reduces costs and time for installation of equipment at the facility.

The block design of the installation also significantly reduces the cost of transporting equipment to the installation site.

The block is a block-modular building consisting of two rooms. Filter separators with piping, shut-off valves, control valves, instrumentation and control systems are installed in the first room. The remotely controlled valves are equipped with electric drives. The second room houses the electrical cabinets of the following systems: power supply, ventilation, heating, gas pollution control, automatic fire extinguishing, and process control. The block-modular building consists of a welded base made of metal profiles, a metal welded frame, with walls made of sandwich panels with a thermal insulation thickness of 80 mm.

The installed technological equipment, instrumentation and control systems ensure round-the-clock, continuous operation of the unit (except for the time for scheduled maintenance), without the constant presence of maintenance personnel.

Two SGV-7F separators are installed in the process room, with gas inlet and outlet pipelines, automatic condensate discharge pipelines, a drainage pipeline and a flare purge pipeline.

100% redundancy is provided for the devices (one is in operation, the second is in reserve). In each of them, in a single housing, there is a separation part for pre-cleaning the gas stream and a filtration part for fine cleaning. Each of the cavities of the device is equipped with its own liquid discharge pipeline.

Electric shut-off and control valves and manually operated ball valves are installed on the liquid discharge pipelines. For the possibility of automatic discharge of liquid from the cavities of the device, each of them is equipped with a remote level measuring chamber with R0SEMOUNT-3301 level sensors to monitor the current liquid level and an alarm for an emergency low level of liquid 1. The device is also equipped with a drainage pipeline for emptying during maintenance. A control valve and a manually operated ball valve are installed on the drainage pipeline. A pressure gauge is installed on the inlet pipeline for local and remote monitoring of pressure and differential pressure on the filter element.

The main element of the block separation unit is the SGV-7 gas separator.

The main advantages of our block separation units are:

- high efficiency of gas purification from droplet moisture and mechanical impurities;

- high factory readiness units are available;

- the package includes counter flanges and an automation system;

- the possibility of execution in a heated block box of transport dimensions, including fire alarm and gas pollution control systems;

- redundancy of separators and main liquid discharge devices, if necessary;

- the ability to complete the units with the necessary gas metering devices.

The installation is a complex of separation equipment having 2 separation stages in its harness, with shut-off and measuring fittings, and mounted measuring equipment mounted on a frame.

The scope of delivery of the installation includes the required number of pipelines with piping strapping and shut-off valves. The length of the pipelines and the number of hinges are determined by the customer and indicated in the general view drawing and working design documentation.

To automate the operation process, the installation is equipped with valves with electric actuators, level sensors, flow meters on the purified gas and liquid drainage lines, pressure and temperature sensors, and safety valve.

The installation automation system (ACS) is made in the form of a single software and hardware complex based on a programmable controller, and is a system that includes:

- sensors for obtaining information about the progress of the technological process installed directly on the equipment,

- electric actuating mechanisms installed in the harness of the BSU,

- Operator's automated control system, which allows remote control of the technological process of well exploration,

- a source of autonomous power supply with the capacity necessary for the normal operation of the ACS control cabinet and actuators.

The installation also has the ability to connect to the automated process control system of the facility in order to transfer the main operating parameters to the automated control system of the fishing operator. The data transfer protocol is agreed separately at the development stage of the ACS installation and agreed with the Customer.

Sampling pipes are provided for liquid and gas sampling at the inlet and outlet of the installation, as well as on the drain line.

To prevent hydrate formation, hydrate inhibitor supply pipes are provided at the inlet and outlet of the installation.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.